In contrast to conventional screws, self-tapping screws tap their own threads as they are inserted into either plastic, wood, or metal. Typically, self-tapping screws come in two varieties: thread forming and thread tapping.

The definition of a self-tapping screw and the distinction between them and self-drilling screws are covered in this article.

Table of Contents

What is a Self-Tapping Screw?

When screwed into materials like wood, plastic, and metal, self-tapping screws create their own holes. You can make precisely fitted threads by using a screwdriver to attach a self-tapping screw. They are perfect for screwing into places where there is only one-sided access or for joining two different types of materials. For items that must be disassembled and then reassembled along the same threads, such as air conditioners or canopies, self-tapping screws are advantageous.

The two types of self-tapping screws are thread-forming and thread-cutting. Plastic should not be used with thread-forming screws because they will distort the material as they enter. Thread-forming screws stay in the material more firmly, but there is a chance that they could be overtightened, which could cause the material to crack under pressure. While thread-cutting screws, which literally remove some of the material to make room for the screw, are typically used for wood and metal. They do this by forming a threaded path. Thread-cutting screws have the drawback that the threads could come loose when the fastener is taken apart. In that case, when reassembling the item, be sure to use a slightly larger self-tapping screw.

Installing a metal insert into the material at the outset will stop stripping for the long run. After that, you could regularly fasten and unfasten with a screw of the proper size without harming the material. To reduce stress, the inserts are shaped, and as the screw is inserted, they expand.

Self-tapping screws are available in a wide range of tip types, sizes, and head shapes. The length of the screw tip should be considered in relation to the thickness of the material when selecting the appropriate size self-tapping screw. Before threading can start, the drilled screw’s tip needs to have enough room to fully pierce the material. Otherwise, thread stripping will occur during the screw’s driving, preventing the final product from being properly secure.

How to Use Self-Tapping Screws

Choose the appropriate screw type first for the substrate to be fastened. Make sure you have enough space to use a screwdriver or drilling machine and mark the precise location where the screw will be used.

Drilling a pilot hole slightly smaller in diameter than the actual screw size typically helps but is not always required. This enables the screw body to fill the drilled cavity and the threads to pierce the material as it is screwed in. Ensure that the drill bit you use is just a little bit smaller than the self-tapping screw; otherwise, the threads won’t have anything to latch onto as the screw turns in.

By hand, turn the screw in one or two turns while keeping it straight in relation to the hole. This enables you to pick up your screwdriver or drilling device while still leaving the screw in the hole. Screw the self-tapping screw into place with firm, quick movements using a Phillips or flathead screwdriver or drill bit. To avoid head stripping, make sure the self-tapping screw is inserted straight and do not overtighten it.

Thread-Forming Versus Thread-Cutting Self-Tapping Screws

The way the screw is turned in can be used to distinguish between two different classes of self-tapping screws. As they are inserted into the material, thread-forming screws create their own threads. Although thread-cutting screws accomplish the same task, they do so in a fundamentally different manner. In order to remove the material from the area into which the screws are driven, thread-cutting screws have cutting edges that actually cut into the material. Instead of removing any material by cutting it, thread-forming screws displace it, allowing the material to flow around the threads.

Thread Forming Self-Tapping Screws

The material (typically wood, soft plastics, or thin sheet metal) is moved around but not actually removed by these self-tapping screws. When higher stresses are required, they are used. Because no material is taken out, resulting in a zero clearance fit, this method allows for better loosening. In most cases, these screws can resist loosening without the aid of lock washers or other tools intended to stop loosening. Only materials that can accommodate them, such as aluminum, soft steel, and non-ferrous metals, such as these, can be used with thread-tapping screws. Generally speaking, formed threads are thought to be stronger than cut threads because the material’s grain is compressed rather than removed.

Thread Cutting Self-Tapping Screws

Cutting edges are machined into the threads of thread-cutting screws in the form of one or more flutes. As the screw is turned in, the material being screwed into can be removed. Compared to their thread-forming counterparts, thread-cutting screws are more adaptable and can be used on a wider range of materials. Screws that create perfect thread fits have a lot of holding power and resistance to vibration. Additionally, installing these screws quickly and easily speeds up assembly and disassembly. They are more frequently used with metals and wood, and they don’t produce as much stress as thread-forming screws.

By selecting the right self-tapping screw for the job, you can reduce your labor and time costs. Because they don’t need a pilot hole to be drilled, self-drilling screws with sharp tips are used to fasten soft materials. For thicker metals, self-drilling, self-tapping screws work best because they can drill and fasten simultaneously.

What is the Difference Between a Self-Drilling Screw and a Self-Tapping Screw?

One of the most popular types of industrial fasteners is the self-tapping screw. The Industrial Revolution was propelled by the use of self-tapping screws, one of the first engineered fastener products. They were made of hardened steel. Self-tapping screws come in a wide range of styles and varieties today, many of which are designed for particular fastening applications.

Contrary to the terminology used for aerospace or military fasteners, the terminology used in the commercial fastener industry can be vague and frequently lead to misunderstandings. The distinction between self-tapping and self-drilling screws is a prime illustration of this imprecision.

- Despite being frequently referred to as a sheet metal screws due to their extensive use in the sheet metal industry, self-tapping screws can be correctly described as simply tapping screws.

- Whichever name is used, a self-tapping screw (or sheet metal screw), is designated as such because it contains form mating threads (thereby “tapping” the threads) in a pre-drilled hole into which they are driven.

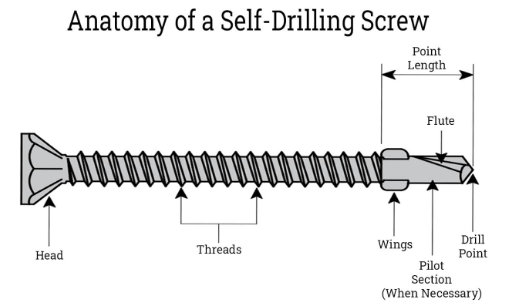

- A self-drilling screw isa type of self-tapping screw that also features a drill point. The precise drill point will simultaneously drill a hole and create the mating threads.

- So where does the ambiguity between the terms come from? In many cases, the person specifying this type of screw will interchange the terms self-tapping screw (or “Self-Tapper”) with a self-drilling screw, but a screw is only a self-drilling screw when it will drill its own hole.

Other similar fasteners that could be considered to be self-tapping screws are:

- Thread-Cutting Screws (TCS) – Screws that can be used to cut threads in a pre-drilled hole are known as thread-cutting screws. In order to achieve thread cutting, thread-cutting screws are divided into various types based on the thread form.

- Thread Rolling Screws (TRS) – Screws that will roll or extrude threads in a pre-drilled hole in the substrate without removing any material are known as thread rolling screws. With zero clearance, these screws create a very tight fit.

In conclusion, the terms “self-tapping” and “self-drilling” are not equivalent. Even though all self-tapping screws are self-drilling screws, not all self-tapping screws are self-drilling screws. Both of these screws are widely used in the commercial, industrial, and construction sectors and are available in a variety of configurations.

FAQs

What is the Purpose of a Self-tapping Screw?

Self-Tapping: Cuts its own thread while being driven into the mating material. A tiny hole is made by the thread-cutting screw as it enters the material, resulting in a close friction fit between the threads. This prevents vibration-induced loosening and enables the parts’ disassembly if necessary.

What is the Difference Between a Self-tapping Screw and a Normal Screw?

Self-tapping screws and conventional screws both have a head, shank, and tip. However, only the former are made to dig their own hole. Traditional screws typically require the use of a pilot hole, which is how they are distinguished from self-tapping screws.

Do You Need to Pre Drill for Self-tapping Screws?

Self-tapping screws can be used with brick, metal, wood, and other materials. These screws cannot drill through metal and require a pilot hole to be pre-drilled before installation.