How to remove a screw with no head? Don’t worry if you’re working on a project around the house and come to a screeching halt because the screw you need to remove doesn’t have a head.

While not difficult, removing a screw without a head requires some ingenuity. In this article, we’ll show you how to get rid of a stripped screw and fix the harm it caused.

Related Post: How To Use A Screw Extractor?

Table of Contents

How To Remove A Screw With No Head?

Step 1

Create a large hole in the exact middle of the screw shaft using a center punch. To give you a place to start the drill, complete this step. Sometimes tapping a tiny nail into the center will work.

Step 2

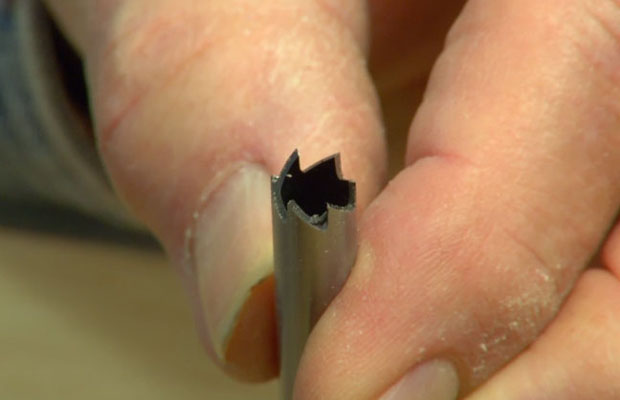

Drill a hole into the shaft starting with a very small drill bit. After that is finished, drill a slightly larger hole in the screw shaft using the next size of bit. When you can use an easy-out tool in the hole, stop drilling.

Step 3

Never use excessive force when turning the tool; doing so could damage the easy-out. The screw shaft must be removed before you stop turning. When you turn the handle of the tool, the interior of the screw shaft will be gripped and turned.

Step 4

If the screw shaft is still resistant to removal, remove the easy-out. Breaking off the easy-out in the hole is definitely not what you want to do.

Step 5

Use the drill to enlarge the hole as necessary to remove everything but the threads.

Step 6

A large plastic-headed pin can be used to peel the screw’s threads away. Remove them from the opening threads.

How To Remove Allen Head Screws Without A Screwdriver?

Without the proper screwdriver, Allen head screws can be difficult to work with. A six-sided hole in the center of the head is a design feature. The Allen wrench slides into it. Allen’s head wrenches frequently have rings attached to them so that it is simple to keep track of them. They typically come in sets. In comparison to other tools, even good Allen wrench sets are affordable. Continue reading to find out more.

Step 1

Find a standard screwdriver that fits firmly between the screw’s two points. Without any wiggle room, it ought to fit. If it fits perfectly, you can frequently use that to turn the Allen head screw. If it’s not an exact match, don’t push it. Simply try the subsequent action.

Step 2

Put a small toothed blade on your hacksaw and get it out. The saw’s very tip should be used for slow cuts. Cutting too deeply could damage the area around the screw or even break it. Cut the material based on the thickness of the screw head.

Step 3

Use a standard screwdriver that snugly fits the groove you just created. Because the screw head has been cut, it is weaker than it was before, so turn the screw slowly and with caution. Without damaging the surface it is screwed into, your screw should back out easily. Use a standard or Phillips head screw if you need to replace the screw later.

How To Prevent Stripped Or Broken Screws?

- Choose the appropriate screws for the job. For instance, common drywall screws may not be able to penetrate some woods in longer sizes due to their brittleness.

- Purchase a set of drill bits that enables you to create pilot holes that are the appropriate size for your screws. Choose the pilot hole size that is appropriate for your screws and type of wood by referring to the chart below. (To prevent the wood from splitting, pilot holes for hardwoods are a little larger.)

The Bottom Line

You should now be able to remove a screw without a head, in my opinion. It’s not that difficult, is it?

Please leave your questions, and we will do our best to assist you.